How Zemic Load Cells are used to innovate the Aerospace Industry

Zemic load cells & Noordung Labs

- Development of hybrid and liquid rocket engines

- Precise thrust measurement for engine testing

- Load cell suited for dynamic aerospace simulations

- Reliable data under vibration and high acceleration

- Engineering support for optimal integration

- Improved safety and predictability in engine development

Noordung Labs is a student led aerospace group based at the University of Ljubljana, Slovenia. Founded in 2018, Noordung Labs brings together students from various disciplines to design and build advanced small-scale rockets with the goal of making a meaningful impact on the European aerospace industry.

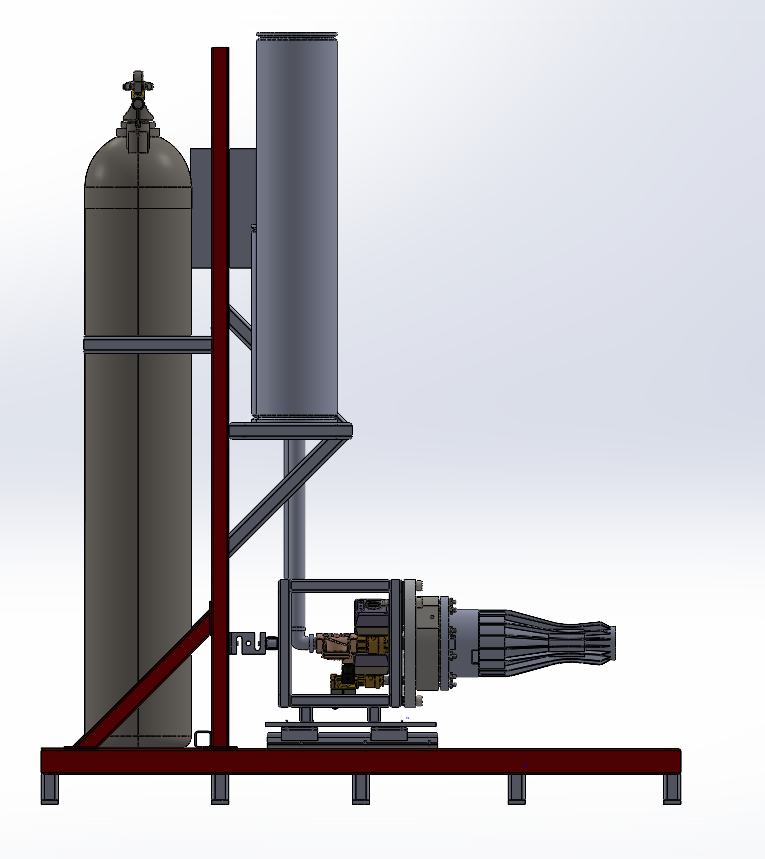

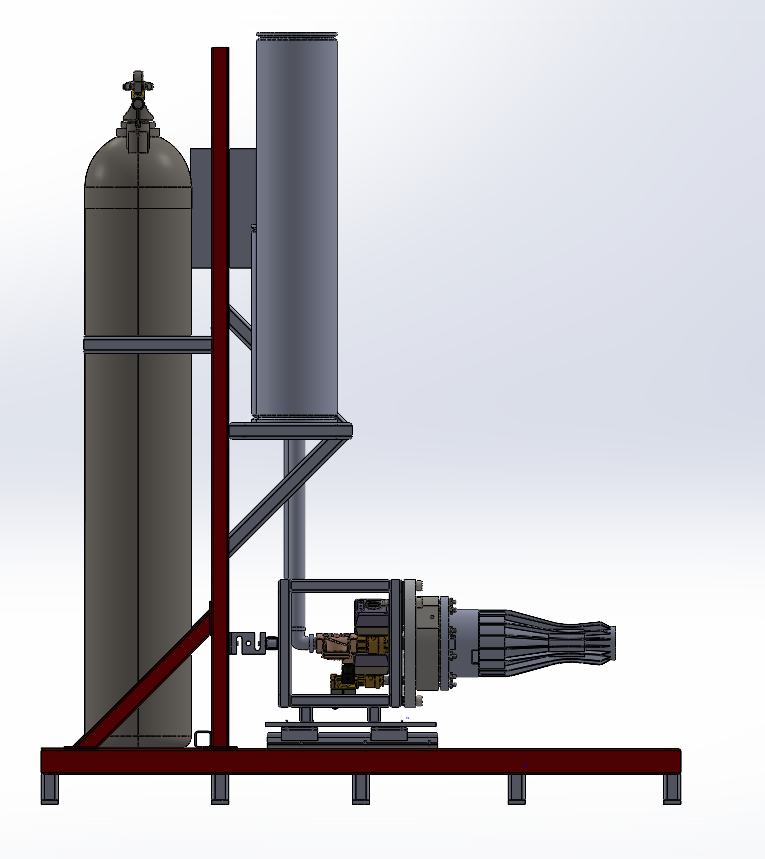

Their projects include developing hybrid rocket engines, an electrically actuated thrust vector control (TVC) system, with current efforts centered on the development of a liquid propellant rocket engine. Noordung faced a critical challenge for their test stands, validating engine performance and ensuring system reliability under realistic conditions. This required a highly precise, reliable and OIML C3-certified load cell solution.

How Zemic advised Noordung Labs

Zemic Europe stayed closely involved as Noordung Labs moved from concept to a working test stand. The team valued Zemic’s responsive support while incorporating the H3 load cell into their custom signal‑processing and data‑acquisition setup.

One practical advantage for Noordung Labs was that the H3’s S‑type aligned well with the mechanical layout of their engine test stand. This allowed them to mount the load cell axially behind the propellant tanks, keeping the installation simple and predictable while they focused on the rest of the propulsion system.

With the H3 load cell incorporated into their setup, the team could gather the detailed force data needed to validate their internally developed simulation models. This helped them address anomalies in the development phase, refine their designs more confidently and enabled more informed decisions for a reliable and predictable propulsion system.

Key benefits for Noordung Labs:

- A load cell that fits easily into their test stand layout

- Responsive support during integration of custom electronics

- Clear, consistent thrust data to support engineering decisions

Which Zemic load cell is being used?

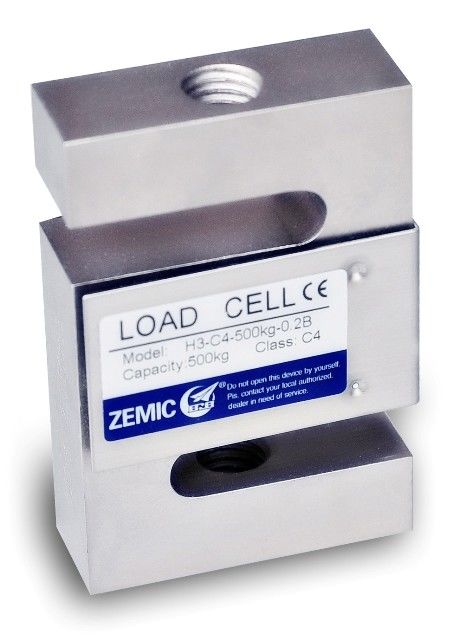

Noordung Labs uses the Zemic H3 S‑type load cell, a nickel‑plated alloy steel model suited for both tension and compression applications.

“We selected the Zemic Europe H3 load cell based on several key criteria. First, we required a model with OIML C3 certification to ensure the necessary precision for our application, particularly achieving a resolution close to 1 gram. […] We opted for the nickel-plated steel variant, which offered a strong balance between performance and cost efficiency. […] The S-type design of the H3 load cell also aligns well with our setup, enabling axial mounting directly behind the propellant tanks.”

- Noordung Labs

The H3 is widely used in industrial and test‑stand environments thanks to its stability, broad capacity range, and durability under demanding conditions. For Noordung Labs, this meant consistent thrust measurements even during rapid load changes and vibration‑heavy engine tests.

Key characteristics of the H3 load cell:

- Nickel‑plated alloy steel construction

- Protection class: IP67 for reliable operation in harsh test conditions

- S‑type design for both tension and compression applications

- Wide capacity range: 25 kg – 30 t

- OIML R60 approval (C3/C4 depending on capacity)

Zemic has a specially equipped sensor department, for the design, sampling and production of custom made load cells and strain gauges. Our engineers are continuously working on special custom made force sensors and strain gauge solutions. We enjoy the challenge of developing the best weighing solution for each project.

“An additional factor in our decision was Zemic’s responsive and knowledgeable customer support, which provided confidence throughout the selection and integration process.”

- Noordung Labs

You can find more information about our load cells; like the different types and characteristics, here:

About the Noordung Labs Engine Test Stand

The engine test stand developed by Noordung Labs is the core platform used to evaluate their hybrid and liquid rocket engines under controlled, realistic conditions. Designed and built entirely by the student team, it enables safe testing of ignition behavior, throttle response and overall engine stability throughout each development stage.

The stand features custom‑developed electronics for engine control, data logging, communication and real‑time monitoring. This setup allows the team to capture detailed performance information and compare physical test results with their own simulation models. By analyzing these measurements, Noordung Labs can identify irregularities early, improve system reliability and refine their propulsion designs more efficiently.